Production efficiency and cost minimization are key factors influencing the competitiveness of enterprises. One of the tools that plays an increasingly important role in achieving these goals is the automation of technological processes. This is also reflected in the context of microbiological diagnostics, as evidenced by the Bactomatic device. Check how this solution – through advanced process automation – can help you optimize production costs and improve its quality.

Automation of technological processes – the key to production efficiency

Automation of production processes is now an integral part of many industries. Thanks to it, companies can significantly increase the efficiency of their operations while significantly reducing costs. One area where automation is showing significant impact is microbiological diagnostics, where analyzes must be precise, fast and reliable.

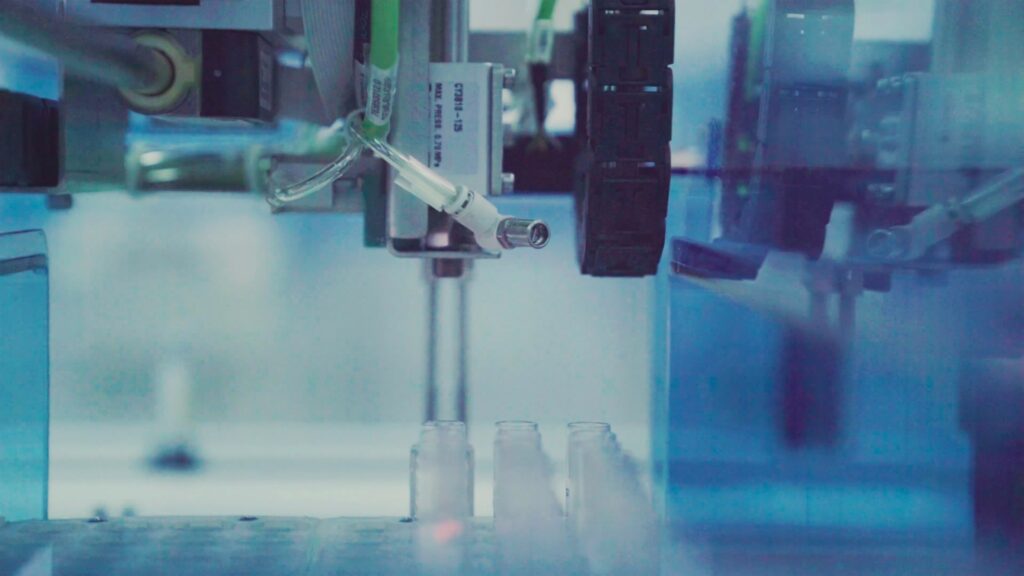

Bactomatic is a perfect example of how advanced automation of technological processes can contribute to the optimization of production costs. This device enables simultaneous performance of many microbiological tests, shortening the time and workload of specialists. Thanks to this, we gain not only in efficiency, but also in costs.

Using Bactomatic in laboratories

In microbiological diagnostic laboratories, automated processes using Bactomatic allow for faster and more precise sample analyses. Traditional methods can require many hours of laboratory work, and time is often a key factor, especially in the case of patients waiting for test results.

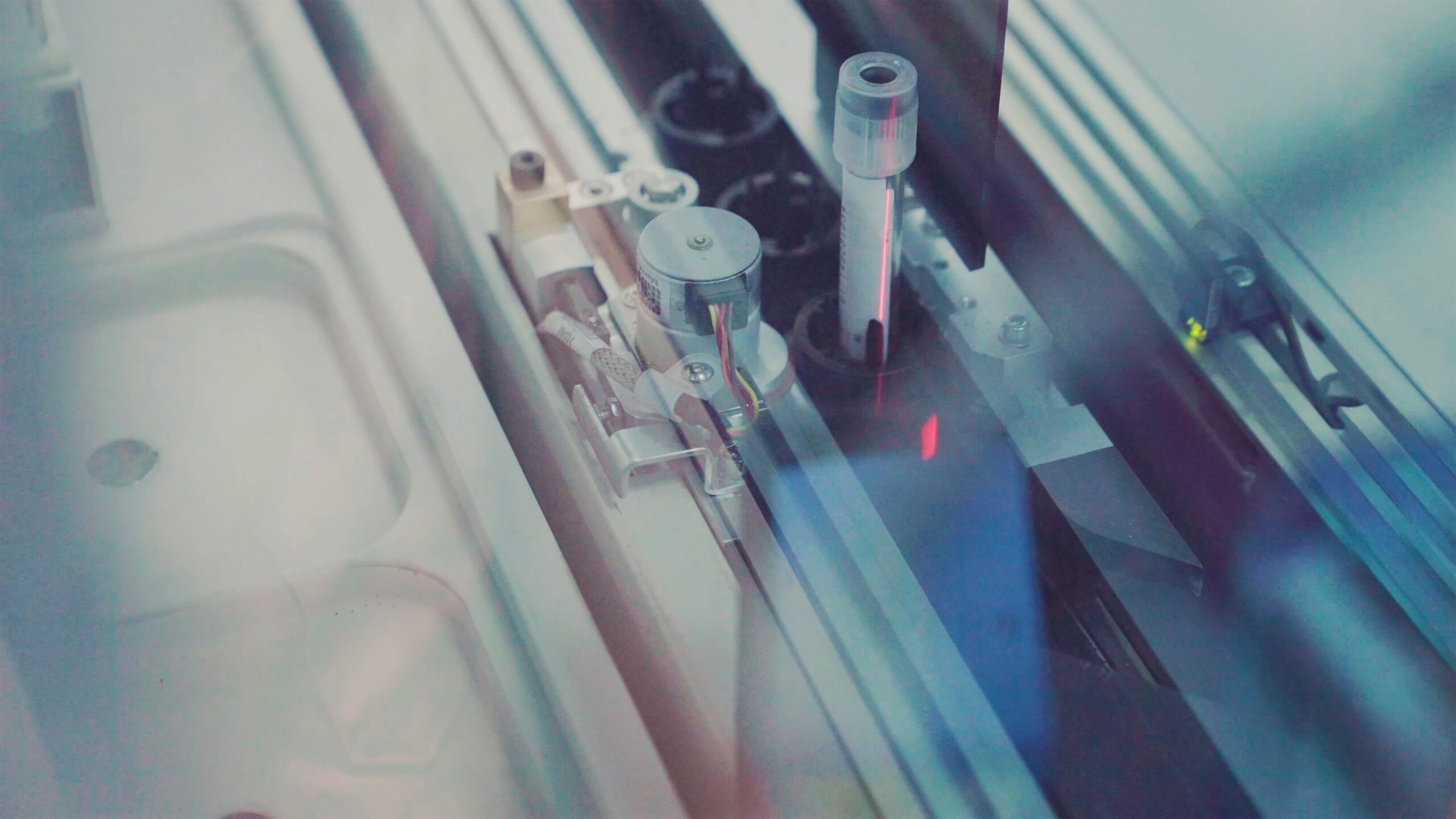

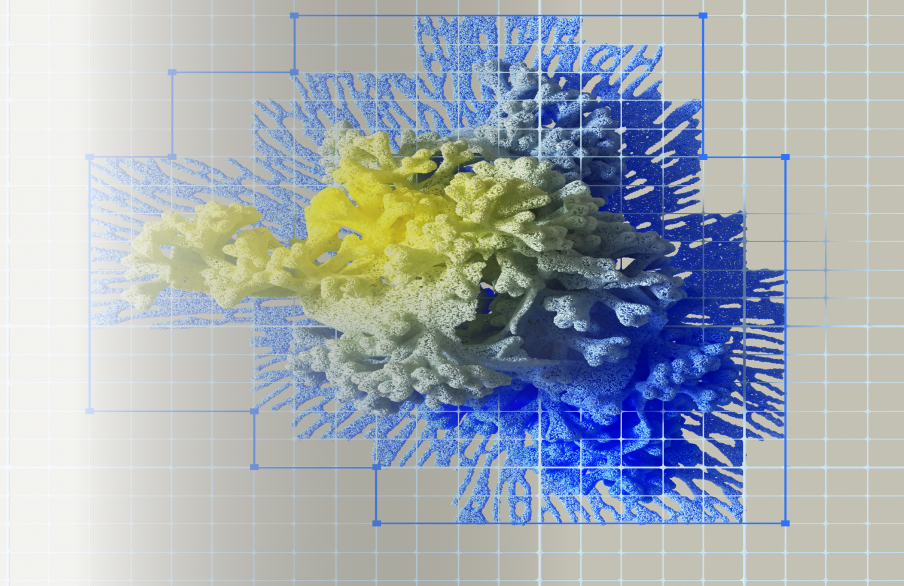

Bactomatic uses hybrid analysis of RGB photos and 3D scanning, which significantly reduces the time needed to detect microbial colonies. Results are available in real time, allowing for immediate responses. This not only translates into faster diagnoses, but also minimizes the risk of human errors, which is extremely important in medicine.

The impact of automation on production costs

Let’s now focus on how Bactomatic helps you optimize your production costs. The first important aspect is the reduction of analysis time. Thanks to automation, laboratory processes become more efficient and specialists can devote their time to more advanced tasks. This reduces not only sample processing time, but also the time in which production can be stopped if microorganisms are detected or product quality issues are encountered. Reducing production downtime is invaluable and can significantly reduce costs. Moreover, Bactomatic enables more accurate counting of grown colonies of microorganisms with an accuracy of min. 95%. This means that we not only save time, but also minimize errors and material waste.

Another important aspect of optimizing production costs is the reduction of storage costs. Traditionally, items awaiting test results must be stored in appropriate conditions, which involves costs. Bactomatic allows you to quickly obtain results, eliminating the need for long-term storage of samples. This significantly reduces costs and contributes to more efficient resource management.

Tomasz Krajewski

CEO