Microbiological diagnostics is the foundation in medicine, the pharmaceutical industry, food industry and many other sectors where precision and speed of analysis are of great importance. However, to meet the challenges of the modern world, it is necessary to gradually implement modern solutions, such as automation of technological processes. In this article, we will look at why automation is becoming a key aspect in microbiological diagnostics and what benefits this innovative approach brings.

Microbiological diagnostics – key challenges

Microbiological diagnostics plays a key role in the fields of medicine, pharmaceutical, food and many other industries. It is a process that allows you to identify microorganisms, analyze their growth and assess their impact on the quality of products. This makes microbiological work pose many challenges to specialists. In this case, the need for precise and quick analysis becomes crucial, which translates directly into production safety, biological purity, as well as the daily work of microbiologists themselves, who can carry out tedious, routine diagnostic work in a faster and more effective way. With all this in mind, automation of technological processes is becoming more and more important to ensure high-quality production in fully safe conditions.

Automation of technological processes – why is it worth it?

In the field of microbiological diagnostics, process automation has great potential to speed up and improve laboratory activities, which may be of key importance, above all, for production safety.

One of the most modern solutions that has the potential to make a real revolution in current microbiological diagnostics is Bactomatic – an innovative device for automating routine microbiological diagnostics. This is a device that allows specialists to conduct many tests simultaneously more quickly and more precisely, reducing the amount of repetitive work to a minimum.

Bactomatic – a modern answer to the challenges of microbiological diagnostics

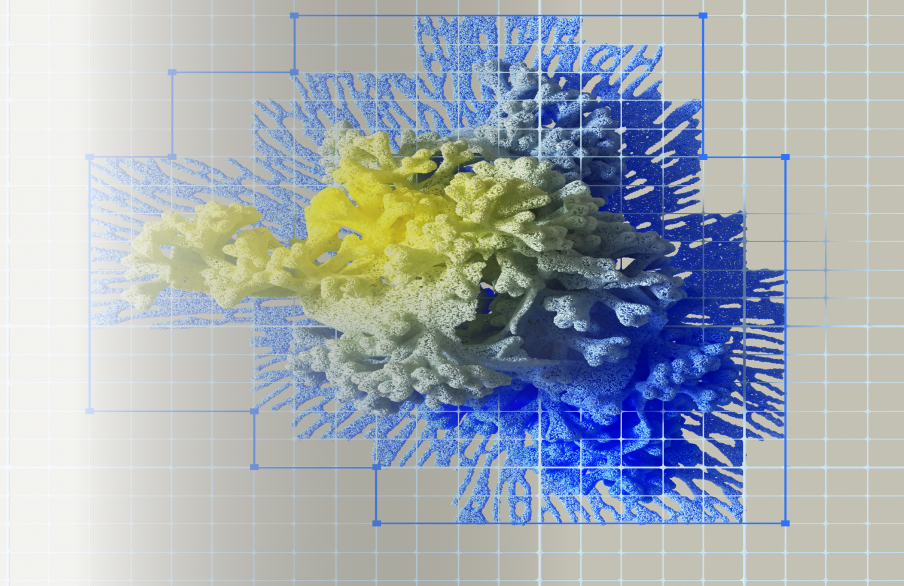

Bactomatic is a device that uses the latest technologies and an advanced data processing pipeline based on artificial intelligence algorithms to accelerate and improve microbiological diagnostics processes. One of the key applications of Bactomatic is testing the microbiological purity of products, early detection of microbial growth, and quantitative and qualitative assessment of microbial colonies grown on solid media.

The primary benefit of using Bactomatic is the automation of monitoring colony growth kinetics. The device uses hybrid analysis of RGB photos and 3D scanning, which significantly shortens the colony detection time and allows for immediate reaction when microorganisms are detected.

Bactomatic also has an innovative vision system that uses three vision methods to measure microbial growth on a daily basis. This data is then analyzed by artificial intelligence, ensuring precise imaging and analysis of the results. The microbiologist receives a report informing him about samples requiring his attention, which allows for an immediate response. The device provides precise analysis results that are available in real time. Thanks to this, specialists can make quick and accurate diagnostic decisions.

The three-module design of Bactomatic is another advantage of this device. Thanks to it, unattended breeding, colony growth monitoring and final diagnostics are possible from the moment the seed is placed in the incubator. This is a solution that significantly improves laboratory processes and saves specialists’ time.

Tomasz Krajewski

CEO